This example shows how to create a simple Weld Builder job for a weaving fillet weld.

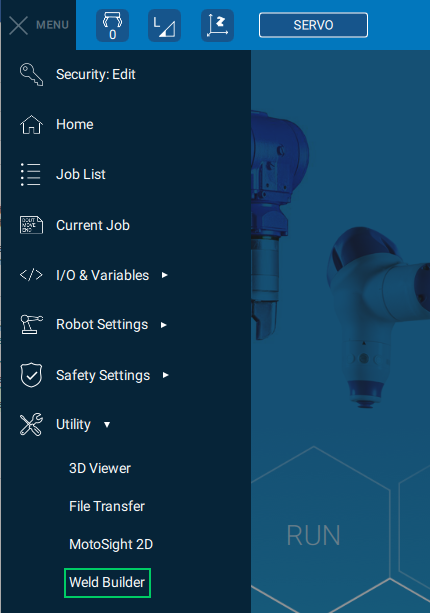

Open the Weld Builder application

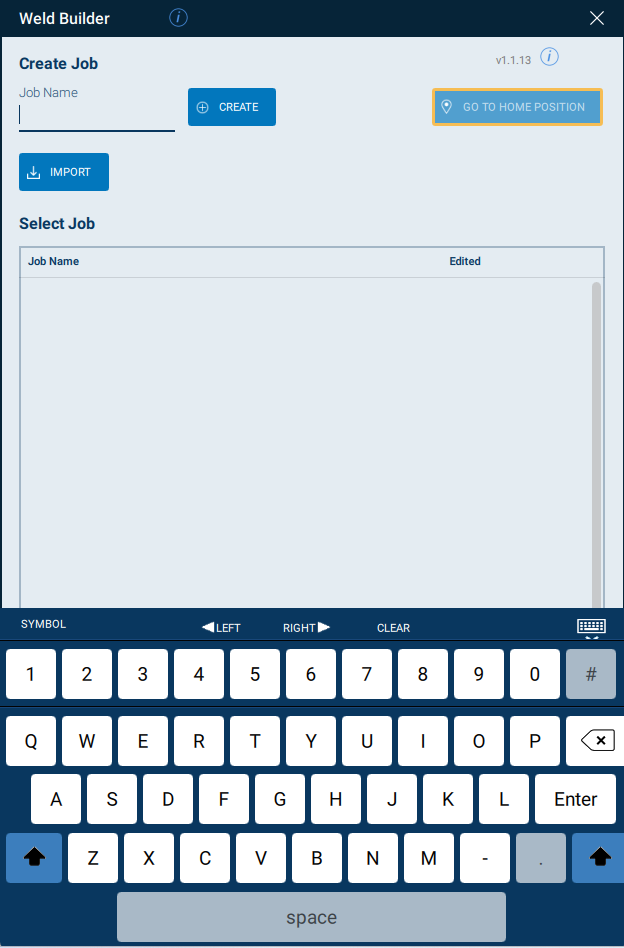

Start Page

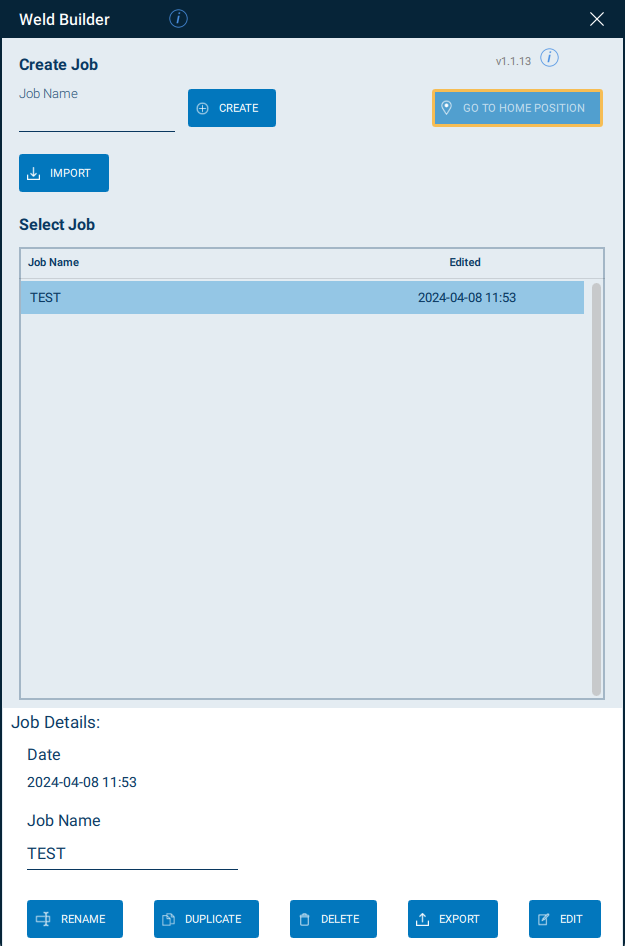

Create Job - If the Program Page doesn’t open automatically, click the Edit button.

Job Manager

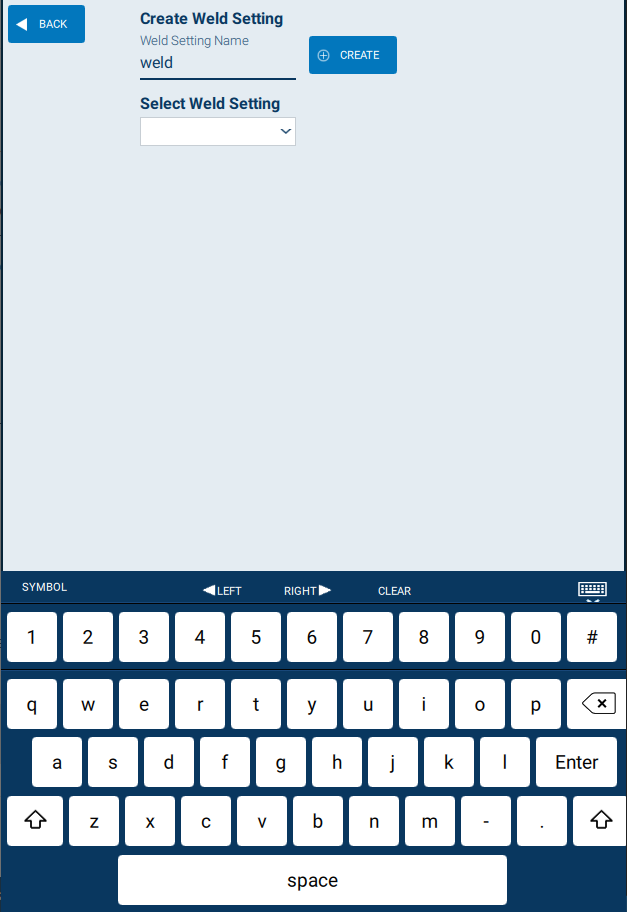

- create a weld setting with the name

weld

Create Weld Setting

- create a weld setting with the name

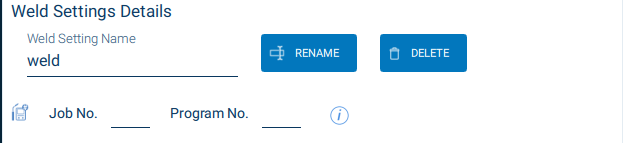

Depending on the used welding power source there have to be set a different number of settings.

Please have a look which parameters are displayed in the Weld Settings Details.

Welding Power Source Settings - Assign your welding power source to a valid job number

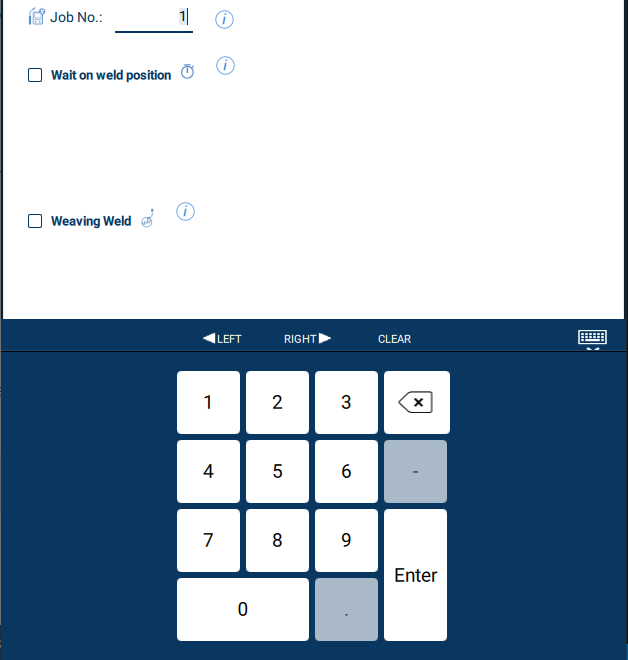

- Set job no to this chosen number

Set Job Number

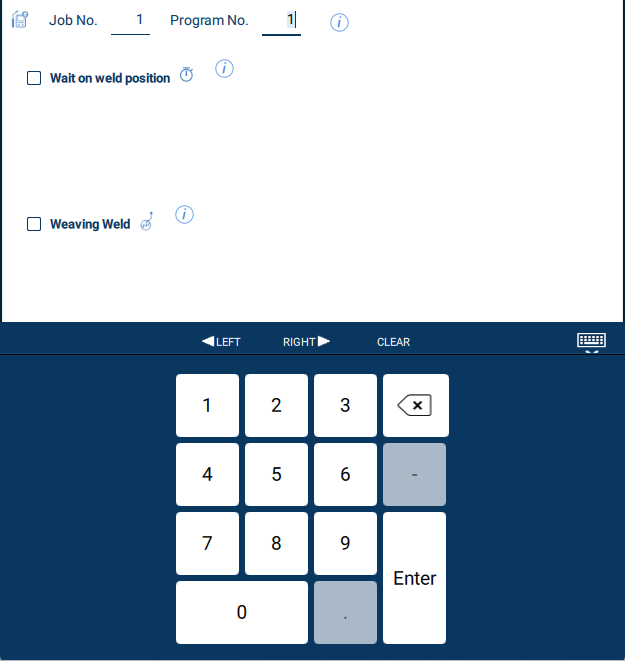

- Assign your welding power source to a valid program number

- Set program no to this chosen number

Set Program Number

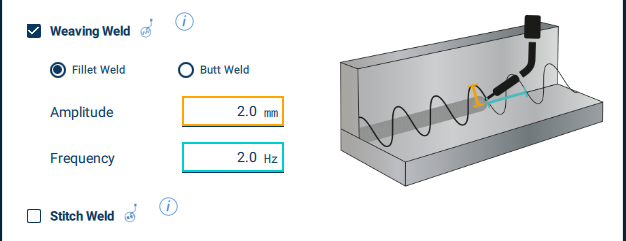

Set Weld Settings ( Weaving Weld )

- Activate Weaving Weld

- Set amplitude to

2 - Set frequency to

2

Weaving Weld

Press Back to go to Program Page

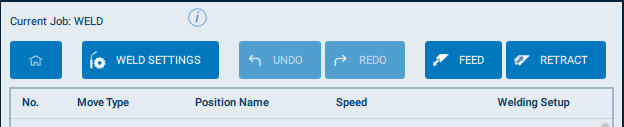

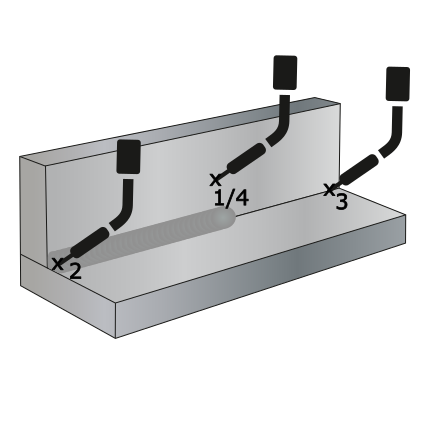

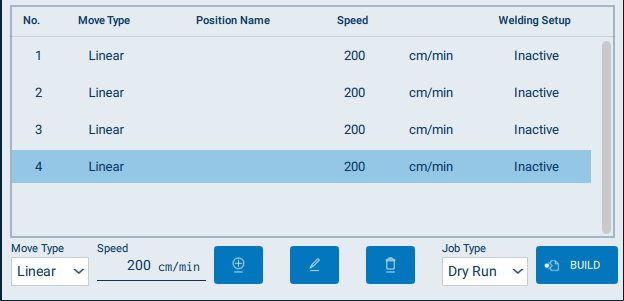

Add 4 positions

Create 4 positions Position Description [1] initial position Initial position of the robot in free space [2] weld start position Start position for welding with 45° torch angle to the component [3] weld end position End position from welding with 45° torch angle to the component [4] initial position Initial position of the robot in free space

Add positions Edit weld position

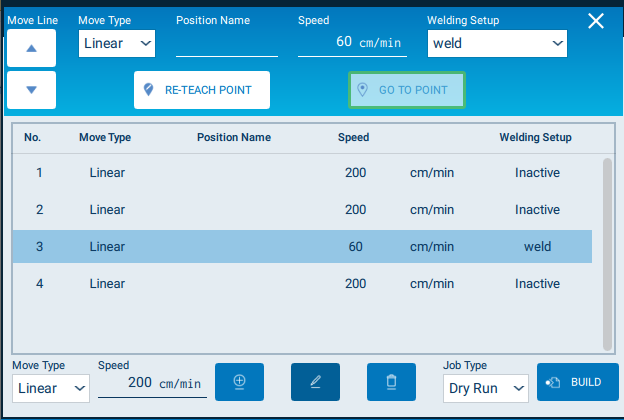

- select line

3 - click Edit button

- change speed to

60cm/min - change Welding Setup to generated Weld Setting Name

weld

Edit weld position

- select line

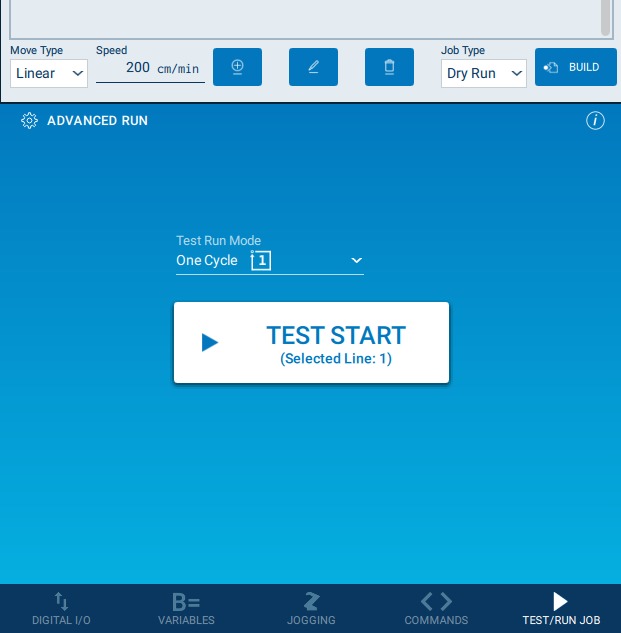

Build and Test job

- check if Job Type is Dry Run

- click Build button

- check if

Servo powerison - click Test Start in Test/Run Job panel

Test run